Home » calibration

Articles Tagged with ''calibration''

Consider these factors before using the internal calibration feature on your device.

Read More

Easily avoided situations regularly encountered by gage makers.

Error by design

February 15, 2018

INDUSTRY HEADLINE

Trescal Acquires ASSI Sistemas e Instrumentación S.L. in Spain

January 17, 2018

QUALITY HEADLINE

ANAB Announces New Online Training Course, Releases 2018 Training Calendar

January 7, 2018

NDT HEADLINE

Element Expands Aerospace NDT Platform with Acquisition of Metals Testing Company

December 19, 2017

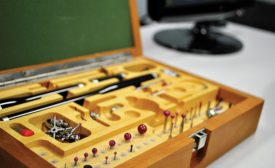

High Precision Specialized Gage Blocks

How precise does this master you need have to be?

December 14, 2017

Thread Ring Calibration Confusion

The problem is one that has plagued the industry for some time.

November 20, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing