Home » calibration

Articles Tagged with ''calibration''

Reports, Certs and Other Documents

The simplest way to get what you want is to spell it out.

February 8, 2019

Standards: Who Writes that Stuff Anyway?

Once a new standard is written that is not the end of it all.

January 15, 2019

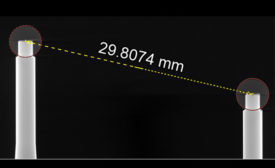

Computed Tomography: Optimizing Large Quantity Automated Measurements

Learn more about automated measurement techniques for large quantity screening applications.

October 8, 2018

INDUSTRY HEADLINE

Mitutoyo America Offers Free Online Video Training and the Opportunity to Earn Certified Credentials

October 2, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing