Home » gages

Articles Tagged with ''gages''

Rules, Ratios and Other Stuff

Even a seemingly straightforward matter can raise questions.

October 1, 2018

Measurement Dispute Resolution

And some advice to avoid such disputes in the first place.

May 7, 2018

INDUSTRY HEADLINE

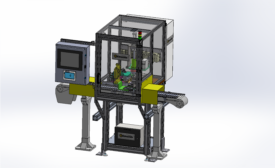

Edmunds Gages Launches Modular Automated Measuring Platform Gaging System

April 16, 2018

Easily avoided situations regularly encountered by gage makers.

Error by design

February 15, 2018

Custom Surface Finish Gages for Hard to Reach Places

When standard devices can’t provide expected results, a better solution is to custom design a gage to suit the specific application.

February 1, 2018

Thread Basics: Go / No-Go Acceptance

It can be beneficial for manufacturing companies to offer thread specific training to both machinists and quality personnel.

January 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing