Home » machine vision

Articles Tagged with ''machine vision''

Reliable detection of even the tiniest scratches.

Read More

Investing in Lighting Control

A number of factors come into play that can affect light intensity.

December 2, 2019

Trends in Machine Vision Sensors

Predictive maintenance, OPC unified architecture, and quantum dot technology are just some of the new buzzwords in this space, according to industry experts.

December 2, 2019

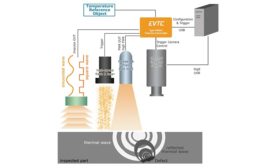

Thermal Imaging for Quality Control

A thermal imaging camera can make infrared light visible.

December 2, 2019

How to Choose a Vision Lighting Technique

5 common vision lighting techniques and 5 critical questions to ask.

September 1, 2019

Self-learning Intelligence for Object Recognition

More and more, advanced artificial intelligence technologies are being incorporated into machine vision systems.

July 1, 2019

Sponsored Content

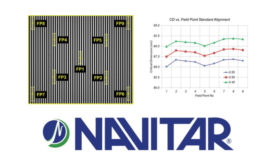

Improvements in Machine Vision Accuracy with Lens-Sensor Active Alignment

July 1, 2019

The Future of Machine Vision Imaging Systems

Beginning with the AIS's camera link standard, the industrial camera portion of the imaging system was standardized.

July 1, 2019

How Machine Vision Cables Impact Machine Vision Performance

Choosing high quality cables is your best approach for long-term productivity and consistent imaging data.

July 1, 2019

Machine Vision Lens Performance

A number of factors are important in lens design, including lens resolution, spatial distortion, and uniformity of illumination.

May 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing