Home » coordinate measurement machine (CMM)

Articles Tagged with ''coordinate measurement machine (CMM)''

Quality 101

Cylindrical ring gages may be used as master gages to set variable measuring tools.

Read More

Guide to Contracting Calibration Services

Many organizations today require ISO/IEC 17025 accredited calibrations, but simply requesting an accredited calibration is not enough.

April 7, 2021

Not All that is Green is Good

There are methods to hide bad product under green numbers.

December 1, 2020

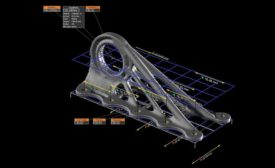

Keeping Up with Additive Manufacturing

AM production enables the creation of parts not possible with traditional technologies through new design concepts, new materials, and new applications, but still presents challenges.

December 1, 2020

Future-Proof Your Quality Systems

Manufacturers must take the opportunity now to bolster their quality systems.

October 31, 2020

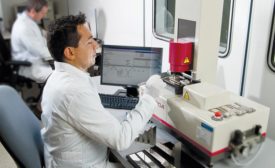

Collaborative Robots: Moving into the Quality Lab

Optipro enhances their world-class optics manufacturing systems using new tools for robotic machine tending and small part measurement.

August 4, 2020

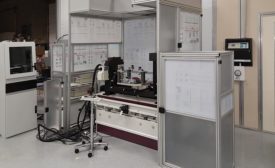

Utilizing CMM Data

Easily import results from CMM reports and incorporate the values into the ballooned drawing and inspection reports.

July 1, 2020

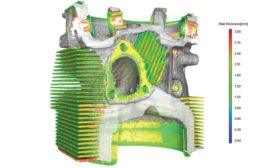

Computed Tomography for Nondestructive Testing

Analysis and visualization software is key to final quality.

June 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing