Home » Computed Tomography (CT)

Articles Tagged with ''Computed Tomography (CT)''

NDT | Back 2 Basics

Besides the automation of a CT system for NDE 4.0, it is very important to digitize the whole process for NDE.

Read More

Aerospace | NDT in Aerospace

CT-Scan Data Analysis and Visualization for Aerospace NDT

For as long as there has been commercial and military flight, aircraft component suppliers have been charged with providing dimensional and process control-related data.

July 8, 2022

NDT | Computed Tomography

How Nondestructive Testing is Driving Sustainable Quality in the Automotive Sector

NDT techniques are available that are just as quick as destructive methods but also offer a more sustainable use of raw materials.

February 8, 2022

NDT | Computed Tomography

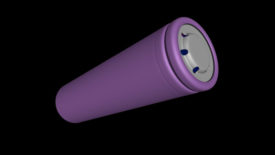

Computed Tomography's Solution to Battery Safety Concerns

A battery is a great example of the value of CT compared to simple radiography.

February 8, 2022

NDT | Trends

Size, Safety and Software: Driving Innovation in Nondestructive Testing of Electronics

There's no doubt that technology is rapidly advancing in the automotive industry.

November 8, 2021

Sponsored Content

White Paper: University Uses Advanced Micro-CT Scanning for Inspection of Historical Artifacts

October 28, 2021

NDT | Computed Tomography

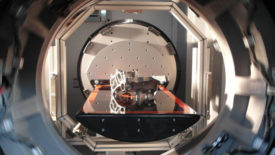

Industrial CT: 3D Inspection and Metrology for 3D Printing

CT inspection of the final part can check that the manufactured part exactly matches the initial 3D design, providing dimensional analysis and metrology of all critical internal dimensions.

October 15, 2021

NDT | Back 2 Basics

The Basics of Digital X-Ray Inspection

Conventional Radiography Will Continue to Have a Pace in NDT, but Digital Radiography is the Future

June 7, 2021

TEST & INSPECTION

Changing Face of Additive Manufacturing Inspection

As Manufacturers Embrace Increasingly Complex Materials and Processes, Their Inspection Methods Evolve with Them.

June 1, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing