Home » computed tomography

Articles Tagged with ''computed tomography''

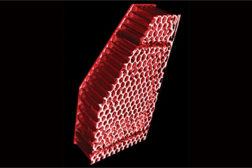

From part analysis to reverse engineering, industrial CT scanning offers fast, nondestructive metrology and validation.

Read More

NDT HEADLINE

Laser Design, Rx Solutions Announce North American Distribution Partnership

October 10, 2014

Industrial Digital Radiography

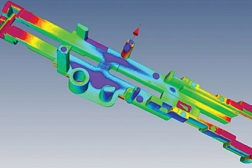

Computed tomography touted as the new driving force.

October 9, 2014

NDT

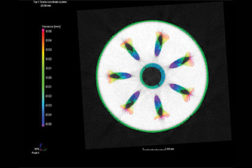

Calibrating X-ray CT Systems

Learn more about the two main methods of calibrating CT data

April 2, 2014

Software & Analysis

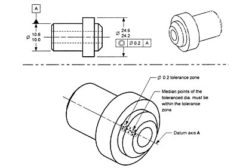

Industrial CT Supports GD&T

Industrial computed tomography can help with your GD&T projects.

September 6, 2013

Test & Inspection

Checking Up on NDT

From more versatile RVI to the rapidly-popular CT technology, NDT has a big future in the medical manufacturing inspection market.

July 1, 2013

Aerospace - NDT in Aerospace

NDT in Aerospace Gains Gravity

While NDT has long been an essential method of testing in the aerospace field, it’s being adopted in a more widespread manner than ever.

July 1, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing