Home » Computed Tomography (CT)

Articles Tagged with ''Computed Tomography (CT)''

Measurement

With its precision, 3D scanning distinguishes itself from conventional measurement tools.

Read More

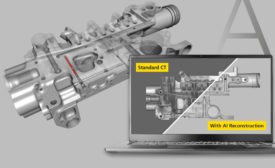

NDT | X-ray CT

High Speed X-ray Computed Tomography for Quality Control

Advances in X-ray computed tomography enable rapid nondestructive, 3-dimensional inspection of die casted and molded parts.

May 20, 2024

NDT | Neutron CT

Neutron Computed Tomography Offers Unique Inspection Capabilities

Unlike standard x-ray computed tomography, neutron CT offers unique capabilities for inspections that cannot be effectively performed using traditional methods.

May 16, 2024

NDT | Computed Tomography

Revolutionizing Manufacturing: The Growing Trends of Industrial CT Scanning

The adoption of industrial CT scanning has transformed product development, manufacturing, and delivery cycles across various industries.

May 15, 2024

NDT | Computed Tomography

The most effective and precise battery inspection technology

It’s the tiniest defects that are the major problems today.

January 8, 2024

NDT | Computed Tomography

Creating the Future of Mobility with CT Inspection of Batteries

Industrial x-ray and CT inspection supports quality control and failure analysis at all stages of a battery's lifecycle.

September 21, 2023

Aerospace | NDT in Aerospace

How Advancing CT Analysis Capabilities Support Collaboration and Product Quality

The looping of CT analysis via digital models can improve every aspect of the design-to-production cycle.

July 10, 2023

NDT | Computed Tomography

Industrial X-ray/Computed Tomography Operator Training: Turning Expectation into Actualization

The system’s potential remains locked inside the machine unless employees are properly trained to operate it.

June 14, 2023

Case Study

A Complete View: Quality Assurance for Premium Headlights

Quality assurance at ZKW Lighting Systems had increasingly reached its limits with conventional measurement technology.

February 10, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing