Home » computed tomography

Articles Tagged with ''computed tomography''

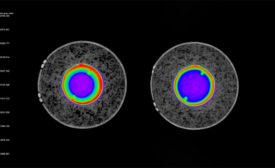

CT provides unparalleled insight into a 3D structure, including its density at every point throughout its volume.

Read More

Understanding Accuracy for Computed Tomography

If you take time to understand these definitions, standards and testing methods, you’ll be able to determine the accuracy of CT in your specific application.

October 5, 2020

Computed Tomography: Back to Basics

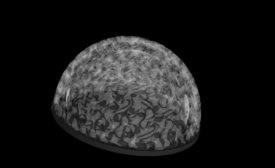

Computed tomography is a powerful nondestructive evaluation (NDE) technique for both 2D and 3D cross-sectional images of an object from X-ray images.

July 1, 2020

Computed Tomography for Nondestructive Testing

Analysis and visualization software is key to final quality.

June 1, 2020

Nondestructive Inspection of Automotive Computers

As with the testing and evaluation of raw materials, controlling the quality of electronic devices is essential

April 8, 2020

How 3D Printing is Changing the Medical Device Field

Being able to manufacture these devices to conform to a patient’s anatomy is a game changer.

March 2, 2020

Seeing is Believing: 2D and 3D X-ray Technologies for Nondestructive Testing

X-ray based techniques have many advantages for inspection and quality control.

November 1, 2019

Sponsored Content

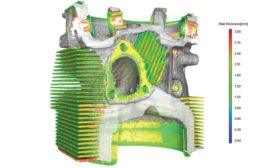

The Future is Now: The Impact of Industrial Computerized Tomography on the Castings Industry

October 18, 2019

NDT

Industrial CT Raises the Bar for Canyon Bicycles

Inspection with the use of industrial X-ray and computed tomography has helped Canyon Bicycles raise the bar on quality and safety.

October 1, 2019

NDT

4 Reasons Why CT is the Best Method for Medical Device Quality Inspection

CT is a huge benefit to the medical device industry and will only continue to grow.

October 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing