Home » computed tomography

Articles Tagged with ''computed tomography''

Managers can now capitalize on the data and be more responsive to production issues as they arise.

Read More

NDT HEADLINE

Speakers Present NDT Discoveries at North Star Imaging’s 2018 Technical Symposium

May 4, 2018

Third-Party Industrial Computed Tomography (CT) and Digital X-ray Inspection Services

Are they right for your business?

April 2, 2018

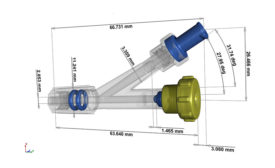

Computed Tomography Analysis Techniques

Industrial computed tomography cuts deep for applications beyond just porosity analysis.

April 2, 2018

Radiography Trends Lead to High Speed CT

Today’s digital radiography is far beyond what early radiographers could have imagined.

April 2, 2018

QUALITY EXCLUSIVE

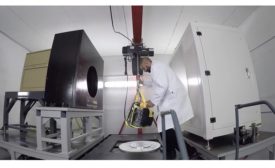

CT Scanning Steps Towards the Future

High-powered CT scanning allows for better inspection of 3D-printed parts.

October 23, 2017

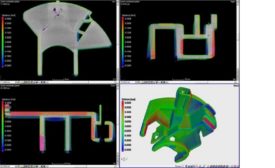

Redefining Aerospace Inspection with CT

While many NDT methods are available, industrial computed tomography is redefining the limits of inspection.

October 17, 2017

INDUSTRY HEADLINE

North Star Imaging Opening New Inspection Lab On East Coast

October 9, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing