Home » coordinate measurement machine (CMM)

Articles Tagged with ''coordinate measurement machine (CMM)''

New Features, Industries Elevate Laser Trackers

A big selling point of recent iterations is seamless integration into a user’s work process.

June 1, 2019

Measurement

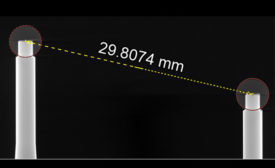

Sensors Unmasked: The Changing Face of CMMs

Evolution is afoot in traditional measurement systems.

May 1, 2019

Quality Case Study: Perfection is Important

The Haas F1 team took a strategic approach to the challenge of quality inspection and reporting.

December 3, 2018

Coordinate Metrology Society

9 Things to Consider When Buying CMM Inspection Software

AN Evaluation checklist helps find the value-add in inspection software.

October 15, 2018

Calibrating Surface Gages for Success

The measurement of surface finish has come a long way in the past 70 years.

October 15, 2018

Computed Tomography: Optimizing Large Quantity Automated Measurements

Learn more about automated measurement techniques for large quantity screening applications.

October 8, 2018

Choosing the Right 3D Scanner

A quality engineer describes how he picks the right tool for the job.

October 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing